Adsorption is the strongest when θ OW is 90° for the particles with a radius bigger than 10 nm, Δ G remove is far greater than the thermal motion energy of themselves, and therefore, adsorption of nanoparticles on the oil/water interface is almost irreversible.

In equation ( 1), Δ G remove is the energy required to remove the particle from the interface, J γ OW is the interfacial tension of oil–water interface, N/m R is the radius of solid particles, m θ OW is the contact angle of particles. (1) Δ G remove = π R 2 γ OW ( 1 ± cos θ OW ) 2

#PICKERING EMULSION SIMULATION SHEAR FREE#

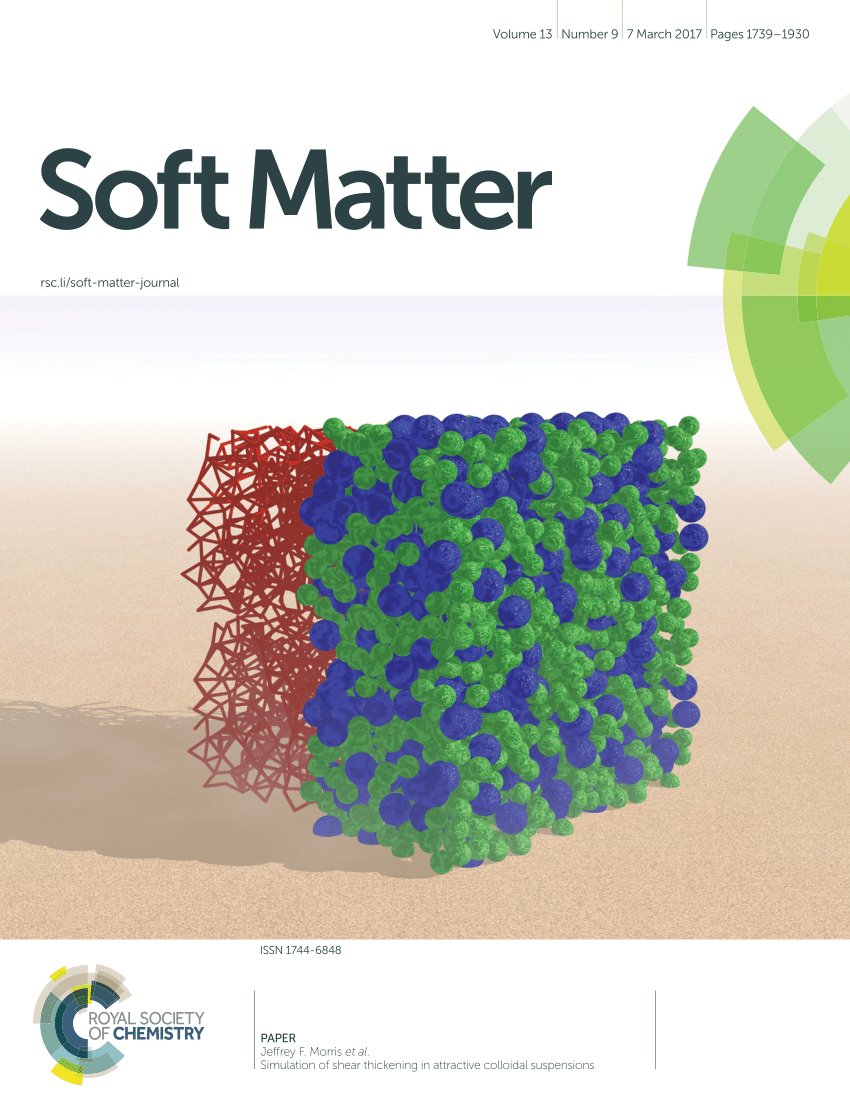

Researches and engineering practice have proved that Pickering emulsions have extremely high stability as adsorption of solid particles under partial wetting conditions is very strong the free energy of adsorption can be calculated by equation ( 1). At present, fabrication methods to form Pickering emulsions mainly include rotor–stator homogenization, high-pressure homogenization, ultrasonic emulsification, membrane emulsification, and microfluidic technology ultrasonic dispersion method is used in this research. In addition, this kind of emulsion has fluidity, magnetism, as well as low preparation cost and consequently can be considered as an alternative to magnetic fluid for viscous drag reduction of magnetic liquids. In terms of industrial applications, crude oil Pickering emulsion stabilized by Fe 3O 4 nanoparticles can be used in crude oil emulsifying transportation due to its high stability and ability of demulsification under strong magnetic field. Fe 3O 4 nanoparticles endow the emulsion with magnetic-responsive functionality. Particles are the key component in the formation of Pickering emulsions, and properties of particles are strongly influenced by their fabrication. During these producing processes, solid particles easily adhere to crude oil under the condition of high temperature and high pressure as a result, the Pickering emulsions are formed. It can also be found in the petroleum industry, such as the process of Pickering foam flooding, oil production by magnetic fluid, and low salinity water flooding. Although no product based on Pickering emulsions is commercialized yet, because of their special properties, Pickering emulsions can be widely used in pharmacy, agriculture, food, catalyst, and other fields. This gel formation also accounts for the instability of the emulsions to shear that we observe caused by shear thinning of the continuous gel and inability of the adsorbed particles to rearrange effectively around the droplets due to their attractive nature.The emulsion stabilized by solid particles instead of surfactants is called Pickering emulsion, which mainly consists of spherical particles (SiO 2, Fe 3O 4, etc.), flaky solids (montmorillonite, kaolin, etc.), graphene oxide, and other particles. Our results suggest that the formation of the emulsions is mostly due to gel formation of the clay particles in the continuous phase, rather than that the clay is an emulsifier. Without surfactant (with only LAPONITE® as stabilizer) the emulsions are stable to coalescence for several weeks, however they destabilize rapidly under shear. We show that the emulsions in the presence of surfactant (with or without clay) are stable to coalescence and shear. This allows us to show directly using confocal microscopy, that the clay particles are not only located at the interface but also aggregate and form a gel in the continuous aqueous phase. To clarify the structure of the emulsion and the role of the clay particles, we have succeeded in fluorescently labelling the clay particles by adsorbing the dye onto the particle surfaces.

#PICKERING EMULSION SIMULATION SHEAR PLUS#

We investigate the role of LAPONITE® particles on high internal phase emulsion stability by considering three different situations: emulsion stabilization by surfactant only, by surfactant plus clay particles, and finally clay particles only. Commonly the stabilization is a combined effect of particle adsorbing at the fluid interface and a particle network in the continuous phase the contribution of each to the overall stability is difficult to assess. Colloidal particles are often used to make Pickering emulsions that are reported to be very stable.

0 kommentar(er)

0 kommentar(er)